Refining the design

I've been thinking more about what the design for the entire assembly might look like. I know that it needs to rotate indefinitely on both the x and y axes. This requires two parts that can rotate and a stationary base. There are several problems I need to solve: how to connect the moving pieces, how to actuate the movement, how to transmit power through the moving parts, etc.

Power transmission

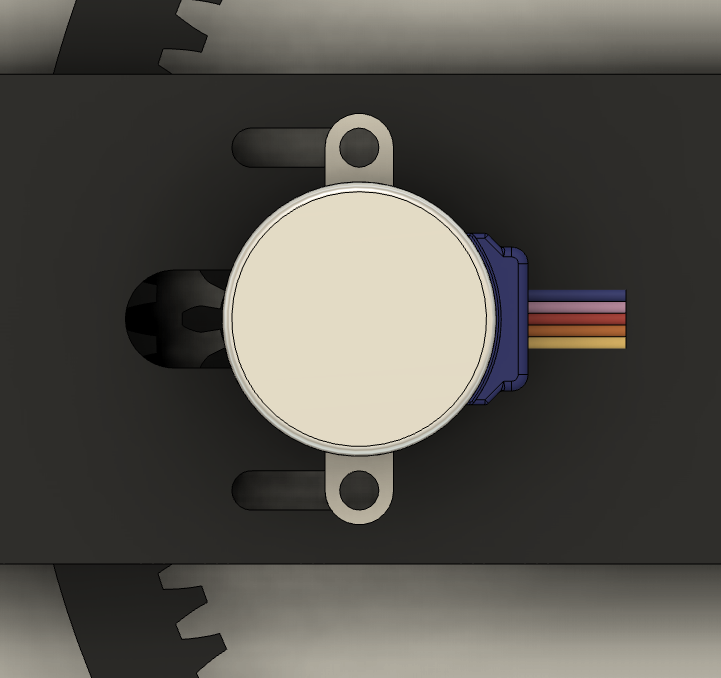

How do you prevent cables from tangling when transmitting power through a moving structure? There's a device called a slip ring, which is an electromechanical component that enables the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring typically comprises a stationary graphite or metal contact (brush) that rubs on the outer diameter of a rotating metal ring. As the ring rotates, the electric current or signal is conducted through the brush to the ring, creating a continuous connection. I plan to mount all the electronic components on the moving arm, which means I'll only need two wires for power. For my project, I intend to use a slip ring similar to this one.

Connecting moving parts

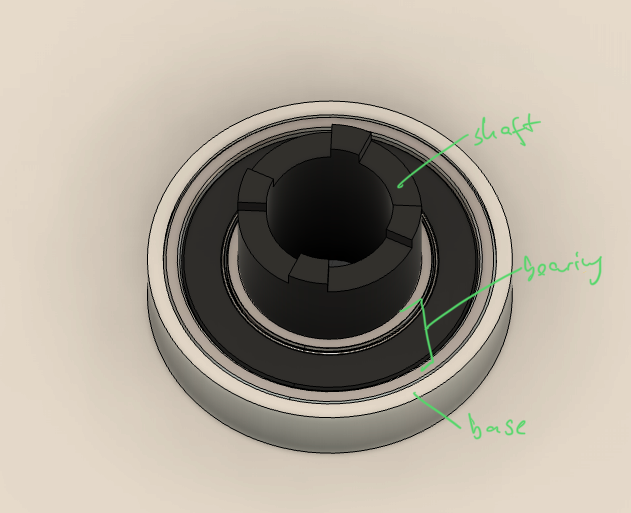

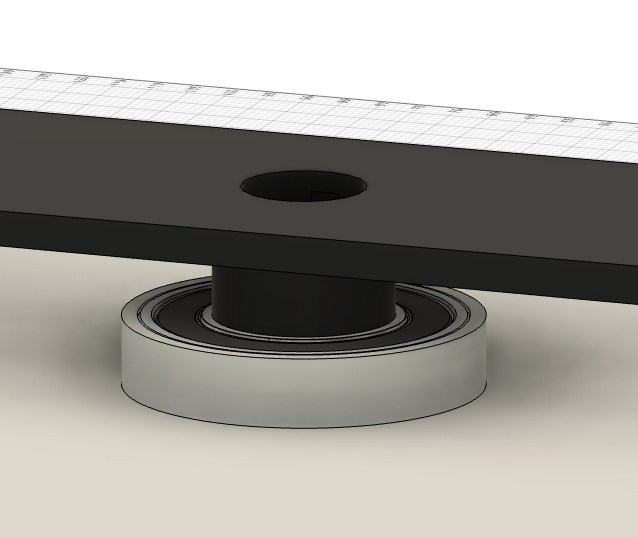

For the rotating arm that will hold the rocket, I'm considering using a hollow shaft mounted into a bearing seated in my stationary base. The cables from the slip ring would then pass through the shaft and bearing.

Another option is to use a "lazy Susan" bearing, which is larger and consists of a stationary part that can be bolted down and a rotating part to which I could attach another moving plate. This might offer more stability than a single shaft for the entire moving assembly, but I'll need to conduct some tests to verify this.

For now, the rocket will be attached to the upper part of the arm, as outlined in my initial design.

Moving parts

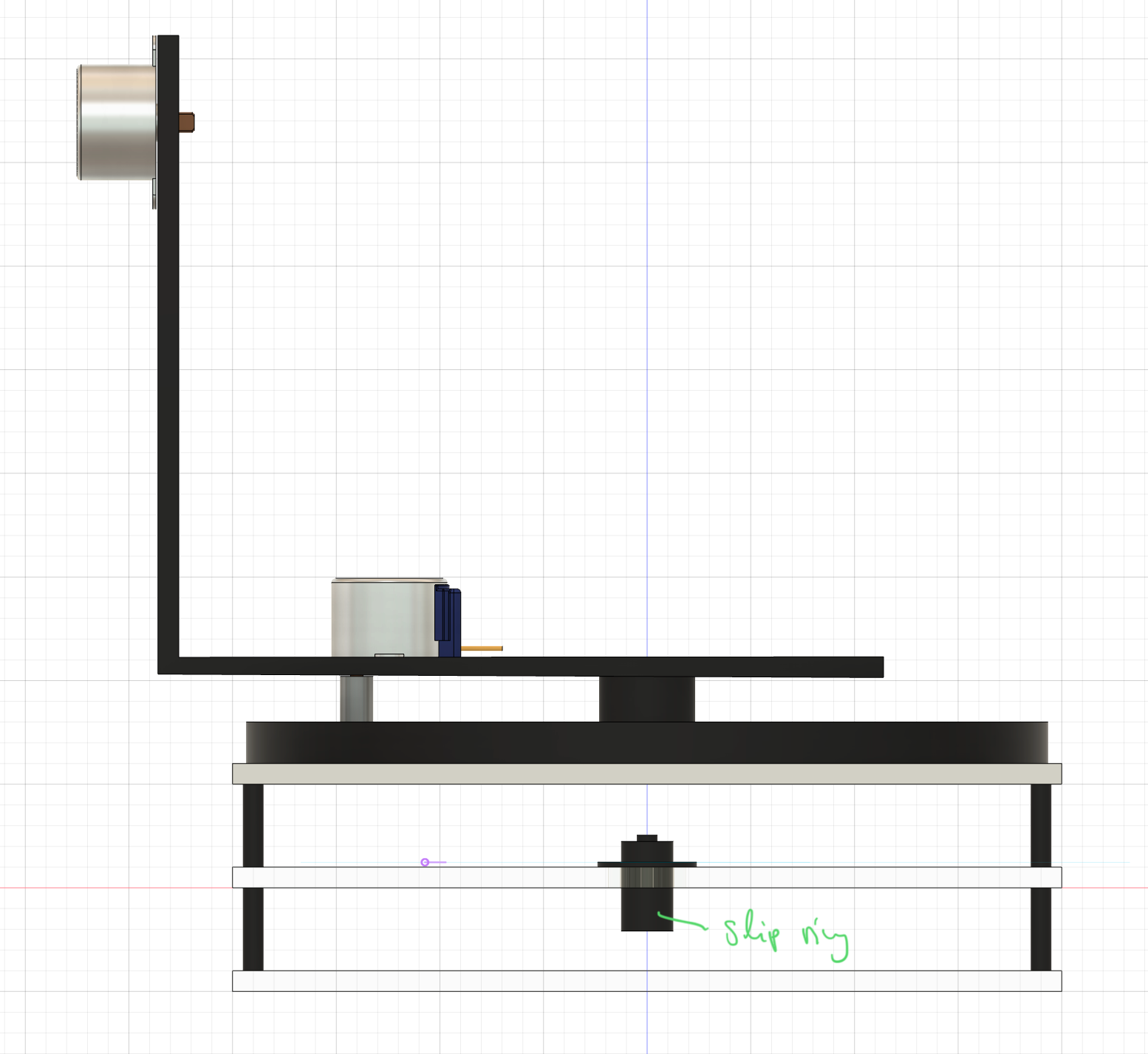

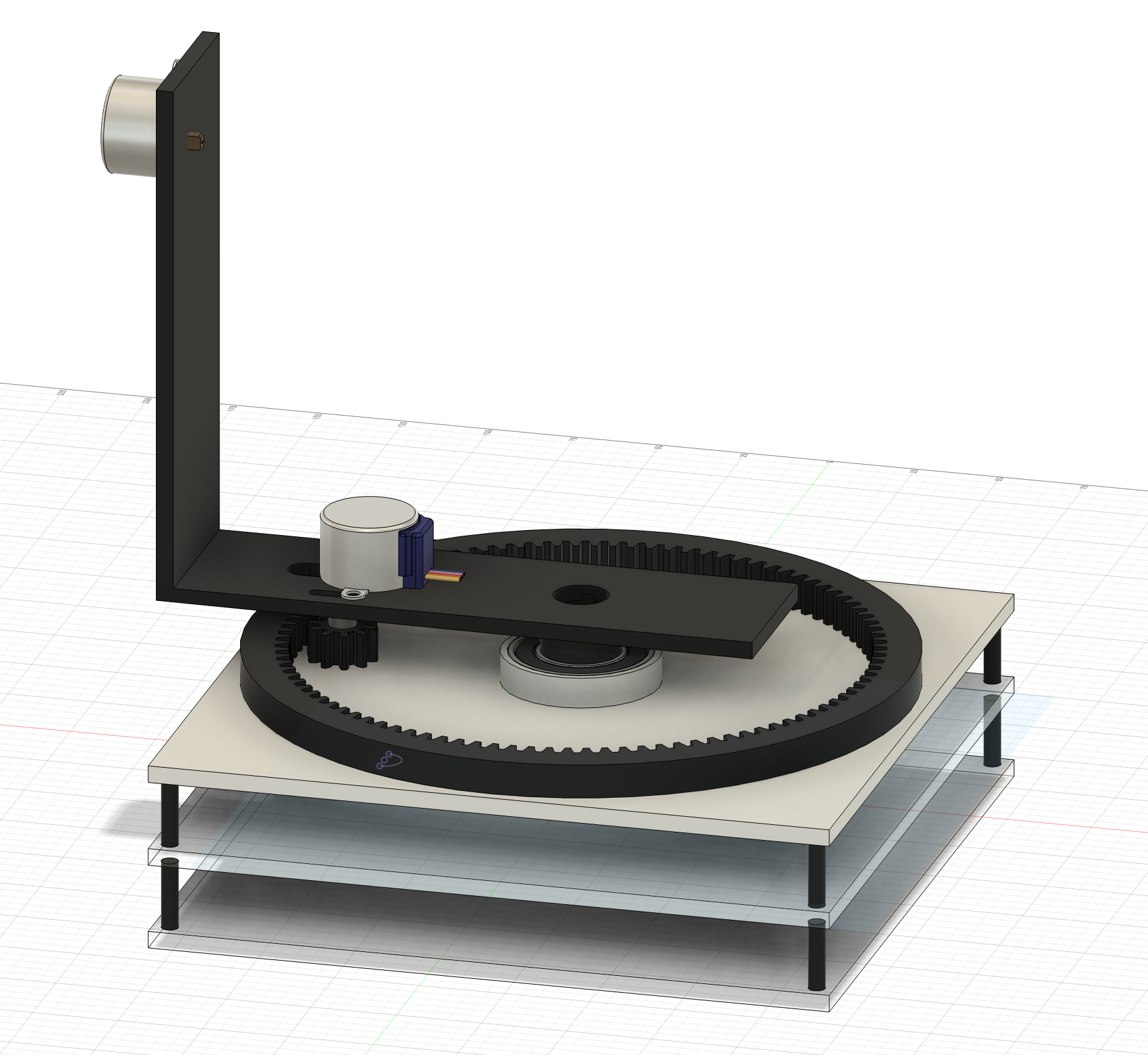

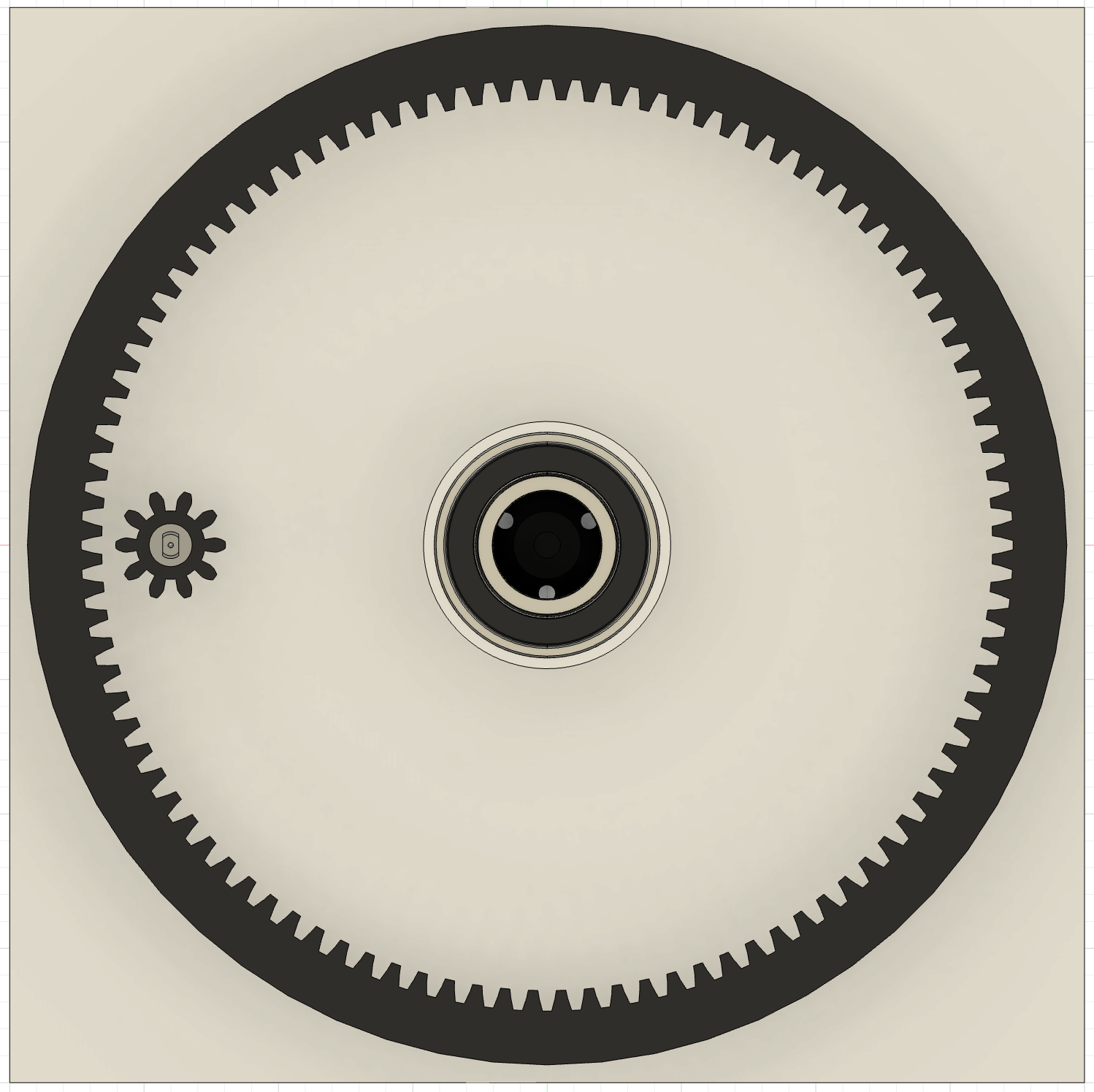

To actuate the parts, I will use two small stepper motors, such as the 28BYJ-48. For power transmission, my plan is to use an "internal" gear on the stationary base and another "external" gear attached to one of the stepper motors on the base of the moving arm. I'm still undecided on the type of gear to use; I'm torn between spur gears and double helical gears.

The motor mount will need to be adjustable to align the gears perfectly.

For the rocket, I may opt for a direct attachment to the motor without gears, but I'll need to determine the required precision—gears may be necessary.

Temporary design

My temporary design consists of three sandwiched plates, separated by four standoffs at each layer. The middle layer will house the slip ring, and the top layer will contain the internal gear and the attachment/bearing (whichever I decide on) for the moving parts.