CNC milling

Another week, another exploration of a fabrication technique. This time, we delve into subtractive manufacturing, specifically CNC milling. CNC stands for Computer Numerical Control, utilizing computer-controlled machines to remove layers from a material or workpiece.

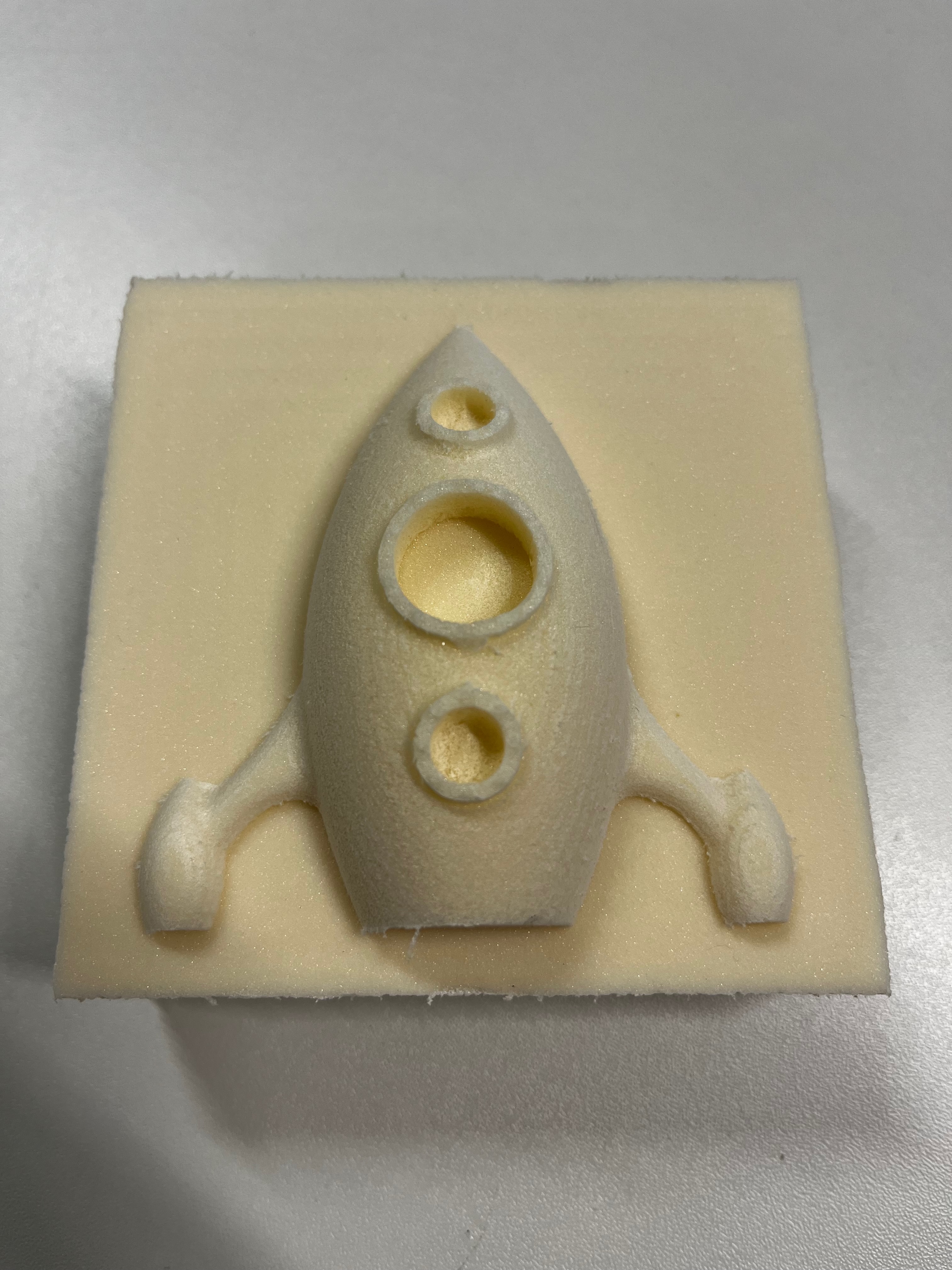

The model I selected for milling is essentially a cut-in-half version of the rocket from my final project with some additional details.

This rocket is crafted from foam, a material that is easy to handle and unlikely to damage the tools even if errors occur.

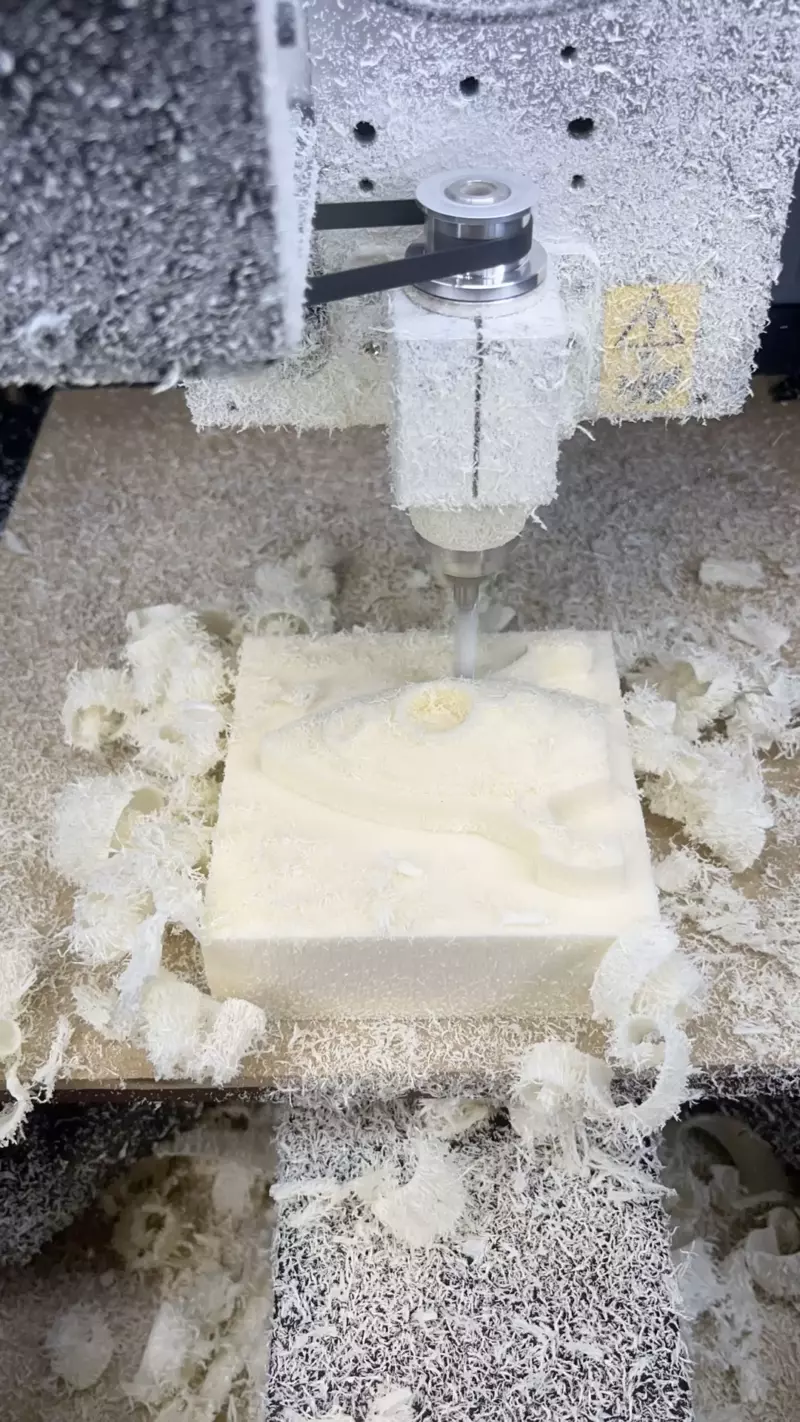

To remove layers from the foam piece, I employed a two-pass approach. The first pass utilizes the adaptive clearing strategy with a 6 mm flat end mill to efficiently remove the bulk of the material.

The second pass employs the morphed spiral toolpath with a 4 mm ball end mill to refine the details and provide a smoother finish.

The finished workpiece already looks pretty good. However, some details aren't quite as pronounced as I'd like them to be, especially the rivets around the windows and the outline of the thrusters. I could probably have gone over it with another pass and a finer tool.